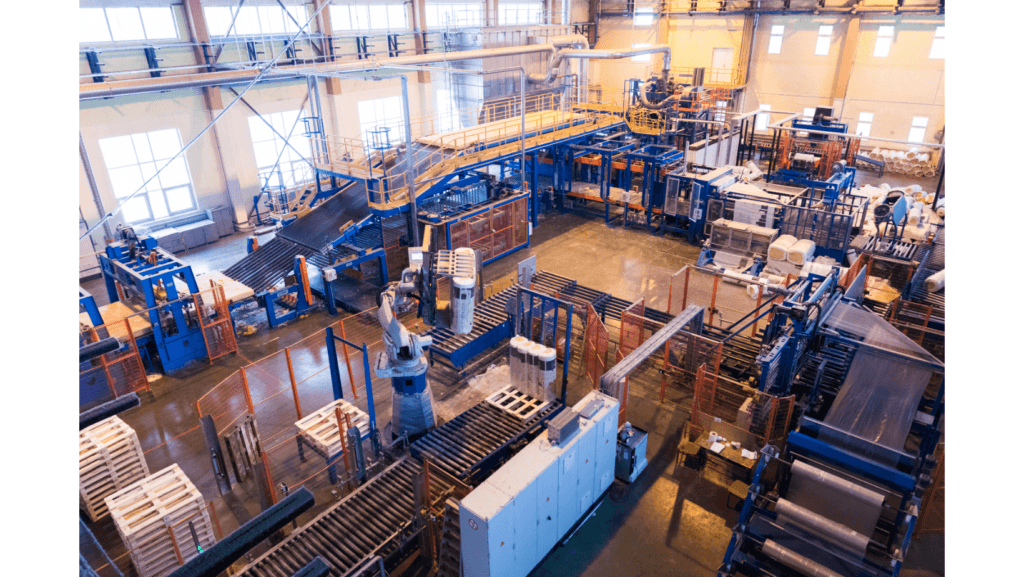

Detection of Problems during manufacturing and its inspection

The maintenance of excellent product quality and the avoidance of faults depend heavily on the early detection of issues during the production process. The significance of identifying issues during manufacturing as well as the numerous inspection techniques used in that industry will be covered in this article. What is a Problem? The perceived gap between […]

Detection of Problems during manufacturing and its inspection Read More »