5-PRINCIPLES FOR PROBLEM-SOLVING

What is 5–Principles?

A tool consists of the following five steps for the problem-solving. They are also referred to as 5P. Manufacturing inspection is a comprehensive and planned technique to ensure quality rather than just a quick peek at the items. The manufacturing industry comprises the five principles of early detection and prevention, consistency and standardized procedures, statistical process control, root cause analysis, and continuous improvement. Manufacturers may maintain high product quality, decrease defects, and gain a competitive edge in the market by thoroughly researching and applying these ideas. These standards emphasize the essential role that manufacturing inspection plays in providing clients with dependable, secure, and high-quality products.

- Investigation and comprehension of the facts

- Identification of causes (why-why analysis)

- Appropriate measures

- Verification of the effects of measures

- Feedback to upstream sources

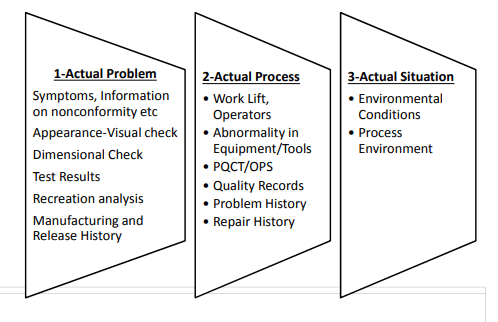

Investigation and Comprehension of the Facts

These principles will enable you to conduct a systematic examination of the situation and pinpoint the underlying reasons for any problems. Begin investigation immediately to avoid impediments, Review the facts by 5W2H. 5W2H is an investigative tool that provides guiding questions to find out the root cause of a problem. After using investigative tools such as 5W2H to observe and Understand facts on the basis of “Three Reality Principles(3A)”. Then all the information is classified on the basis of 5-M. 5M (Man, Material, Machines, Methods, and Money) helps to identify the cause of the problem by drawing the diagram.

5W2H

- Who/Which does this?-Personnel/Process/Machine

- What happened actually? –Problem

- When has this happened?-Timing

- Where has this happened?-Location

- Why did it occur?-Known Explanations

- How has this happened?-In what mode or situation

- How much/How many problems occurred?-Quantity of Problem

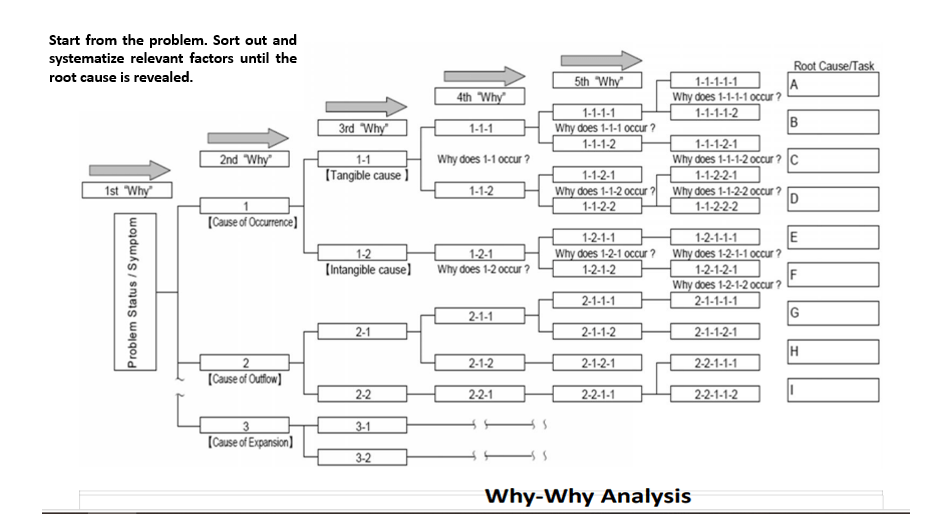

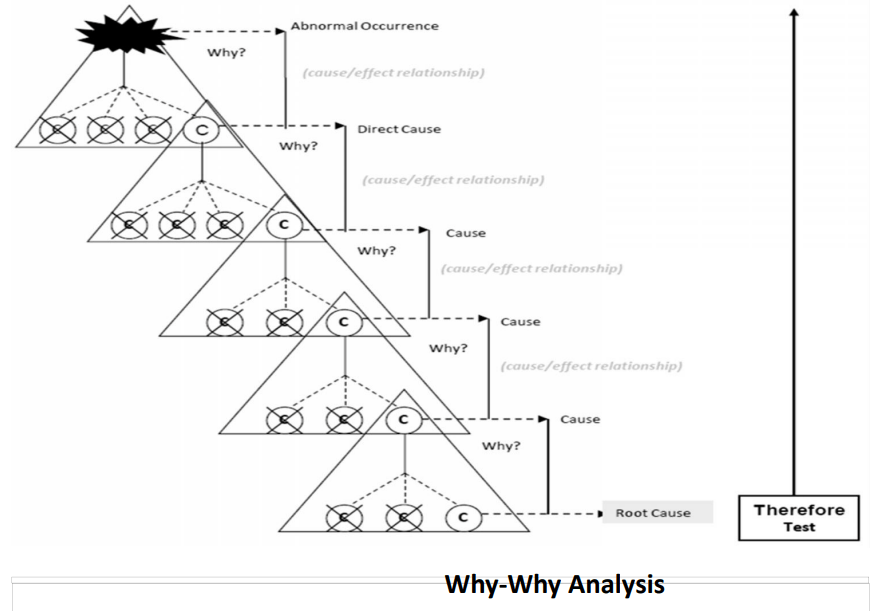

Why-Why Analysis

Why-Why analysis, commonly referred to as the “5 Whys” method, is an effective and popular technique for solving issues in the manufacturing and other industries in the economic system. Its main goal is to pinpoint the root causes of issues by continually asking “why” until you get to the core of a problem.

Why-Why analysis is an essential tool in manufacturing since it improves root cause analysis, cost reduction, process improvement, and product quality enhancement. It encourages data-driven decision-making and a culture of continuous improvement, both of which are crucial in the competitive manufacturing world of today.