CONSULTING SERVICES

how we can help

We’ll ensure that you focus on the opportunities

End-to-end programs.

Expert manufacturing consultancy services

Quality control consulting solutions

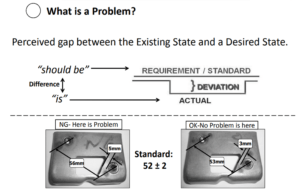

Quality control is the process of manufacturing a product to maintain and improve the quality and efficiency of the product. Basically, it aims to achieve customer satisfaction. During manufacturing three types of products are formed.

Kaizen principles in production

Kaizen is a Japanese philosophy that means positive change or continuous improvements in the production processes of an organization and its output such as product. Many companies utilize the Kaizen Concept to make improvements such as Toyota

Numbers

Client results

Learn more

Frequently Asked Questions

I can contribute in a number of ways to improving your manufacturing procedures:

Process optimization: In order to find gaps and obstacles in your current manufacturing processes, I will analyze them. We can reduce manufacturing times and lower expenses by streamlining and improving these procedures.

Quality Control: To make sure that the products meet or surpass industry standards, I’ll put in place strong quality control systems. By lowering faults, rework, and warranty claims, this can raise the general level of product quality.

Data Analysis: I’ll use data analytics to continuously track and examine key performance indicators (KPIs). Making informed assessments and discovering areas for development can be made easier with the help of this data-driven strategy.

Online consulting is frequently used by manufacturing businesses to streamline operations, boost productivity, cut costs, improve product quality, and adjust to evolving technology and norms.

Cost savings, enhanced product quality, higher output, less downtime, and maintaining competitiveness in the continually changing production environment are all advantages.

Evaluation of Suppliers and Supplier Diversity: Analyze your present suppliers to start. While thinking about diversifying your supplier base to lower the risk of disruptions, find trustworthy and high-quality vendors. Establish precise standards for choosing suppliers.

Inventory for safety stocks and buffers: To prevent unanticipated supply chain interruptions, keep safety stock and buffer inventories for essential components. Based on lead times and demand variations, determine these values.

Lean inventory control: To optimize inventory levels, use lean inventory principles. Reduce irrelevant inventory that takes up money and storage space, while yet making sure that products are accessible to satisfy client demand.

Problem: One company was having trouble with high product defect rates, which increased rework and generated customer complaints.

Solution: I thoroughly analyzed the process, determined the underlying causes of flaws, and put quality assurance measures in place, such as process standardization, personnel training, and improved inspection methods. This resulted in a significant drop in faults and an improvement in product quality.

You can contact through contact us Form

Direct Email on sheikh_naeem@ayomab.com Or you can make live chat through this page.

My core strengths in the journey of my professional experiences are:

CORE STRENGTHS

Welding Specialist Production scheduling Quality Standards Compliance

Cost Reductions Kaizen/5S Training Safety Trainings

ISO Documentation Staff Supervision/Motivation MS Word/Excel/Power Point

Yes, I have 8 years experience in HONDA ATLAS CARS PAKISTAN LIMITED.

Honda is a Japan-based Car Company. It is known for the production of cars and motorcycles. Its most well-known cars are the Civic, City and the Accord.

bilal shah, united kingdoms